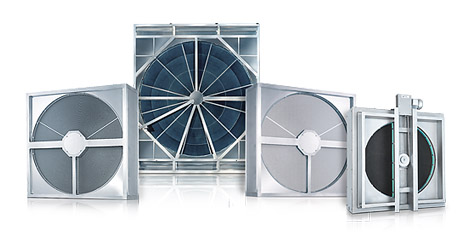

Demand for sorption rotors continues to increase. This type of heat exchanger offers increased performance for the simple reason that in addition to sensible heat (heat that you can feel), they also deliver latent heat in the form of moisture.

This makes them particularly attractive in very humid locations - and in general in any building in which the supply air is passed through a humidifier.

A special zeolite coating process

Klingenburg’s HUgo sorption rotor features a special zeolite coating on its surfaces. Zeolites are highly porous crystals containing tiny channels, in which moisture is collected on the principle of adsorption.

The zeolite coating on a sorption rotor must satisfy several requirements at once:

1. High coating strength (storage mass) on the rotor matrix

2. High transfer of heat and moisture

3. Long service life

4. Low pressure loss

DekaTru® coating technology from Klingenburg meets all these requirements perfectly.

Particle Sizes in the Order of Nanometres

The Klingenburg HUgo sorption rotor is available with a 4A zeolite coating, with particles in the order of nanometres and as a 3A zeolite rotor - both featuring DekaTru® coating technology.

DekaTru® is a synonym for both the special makeup of our zeolites and for the technology actually used to apply the coatings, using specially developed machines.

High Strength of Storage Mass Coating

The zeolite coating must adhere to the surface of the rotor matrix for many years without wearing thin or indeed coming off. despite the high loads and pressures to which it is subjected to.

Storage masses using DekaTru® coating from Klingenburg can be cleaned with a high-pressure water jet without eroding the coating or causing the rotor conduction properties to decline.

Excellent Transfer Properties

DekaTru® technology offers an exceptionally fine and homogenous coating for the rotor matrix. This ensures excellent transfer properties for both temperature and moisture and therefore very high heat and moisture recovery coefficients.

Long Service Life

The German guideline VDI 2067 Sheet 1 specifies a service life of 15 years as the basis for calculating the economic viability of rotary heat exchangers.

Since VDI 2067 Sheet 1 also covers sorption rotors, it is imperative that not only the storage mass, seals, drive and housing are of suitable quality but above all the sorption coating. DekaTru® also meets this requirement in full.

Low Pressure Loss

Thanks to the fine and homogenous particles of its coating, the HUgo sorption rotor offers one of the lowest pressure loss levels on the market.